- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 198 Author: XianDa Publish Time: 2024-12-04 Origin: Site

The world of pharmaceuticals is complex, and one of the key components that often goes unnoticed is the packaging—specifically, the medicine paper box. This article delves into what these boxes are, their significance, design considerations, and the regulations governing them. We will also explore various types of medicine paper boxes, their materials, and their roles in ensuring medication safety.

A medicine paper box is a type of secondary packaging used to contain pharmaceutical products. Unlike primary packaging, which directly holds the medication (like blister packs or bottles), secondary packaging serves to provide additional protection and information. These boxes are essential for branding, safety, and compliance with regulatory standards.

Medicine Paper Box

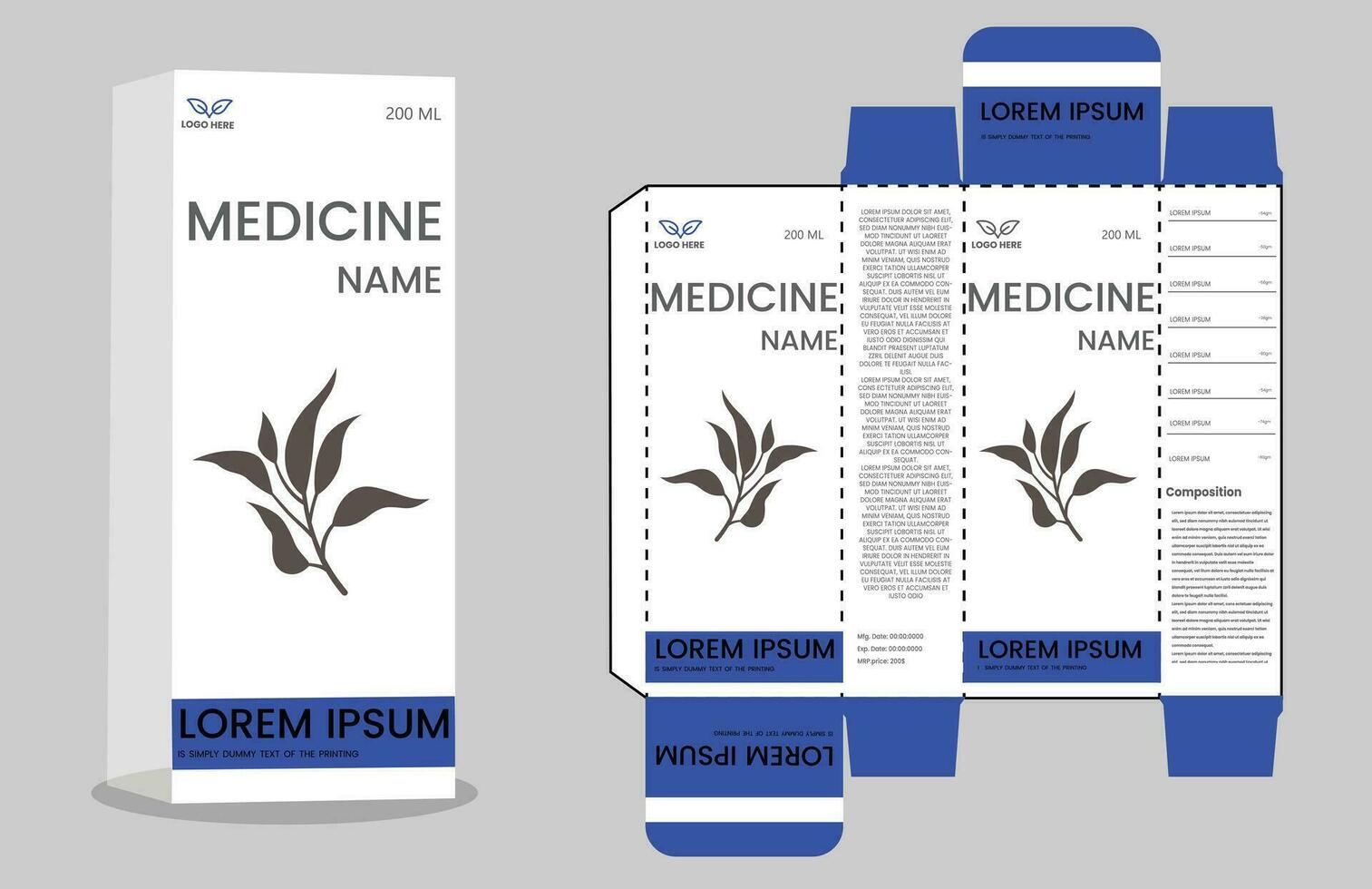

Image: A typical medicine paper box showcasing its design and structure.

1. Protection: Medicine paper boxes protect medications from external factors such as light, moisture, and physical damage during transportation and storage. This is crucial for maintaining the efficacy of the medication.

2. Information: They provide essential information about the product, including dosage instructions, expiration dates, and storage conditions. This helps consumers use medications safely and effectively.

3. Branding: The design and branding on these boxes help consumers identify products quickly and can influence purchasing decisions.

4. Regulatory Compliance: Pharmaceutical packaging must adhere to strict regulations to ensure safety and efficacy. This includes clear labeling and information as mandated by health authorities.

There are several types of medicine paper boxes designed for various pharmaceutical products:

- Tuck End Boxes: These boxes have flaps that tuck into each other for closure. They are commonly used for non-dangerous pharmaceuticals.

- Auto-Lock Bottom Boxes: These boxes feature a bottom that automatically folds into place for quick assembly, making them ideal for high-volume production.

- Display Boxes: Designed for retail environments, these boxes often include hang tabs or windows to showcase the product inside.

- Custom Shapes: Some medicines require unique shapes or sizes for their packaging to ensure safety or comply with specific regulations.

Types of Medicine Paper Boxes

Image: Different types of medicine paper boxes illustrating their unique designs.

The materials used in constructing medicine paper boxes are critical for their functionality:

- Cardboard: Most medicine paper boxes are made from cardboard due to its strength and lightweight properties. Different grades of cardboard (such as C1S) are used depending on the product's requirements.

- Coated Papers: Coatings such as gloss or matte finishes enhance durability and visual appeal while providing a protective layer against moisture and wear.

- Recycled Materials: Increasingly, manufacturers are using recycled materials to create eco-friendly packaging solutions that meet sustainability goals.

When designing a medicine paper box, several factors must be taken into account:

- Regulatory Requirements: Packaging must comply with local and international regulations regarding labeling and safety information.

- User Experience: The design should facilitate easy opening while ensuring that the contents remain secure during transit.

- Visual Appeal: Attractive designs can enhance brand recognition and consumer trust.

Medicine Box Design

Image: A well-designed medicine paper box focusing on user experience.

Advancements in technology have greatly influenced medicine paper box production:

- Smart Packaging: Some modern designs incorporate technology such as QR codes or NFC chips that allow consumers to access additional information about the medication via smartphones. This not only enhances user engagement but also provides an avenue for manufacturers to communicate vital updates regarding their products.

- Tamper-Evident Features: These features help ensure that medications have not been tampered with before reaching the consumer. Tamper-evident seals can include shrink bands or breakable tabs that indicate if a package has been opened.

The pharmaceutical industry is heavily regulated to ensure consumer safety. Key regulations affecting medicine paper boxes include:

- Good Manufacturing Practices (GMP): These guidelines ensure that products are consistently produced and controlled according to quality standards. Compliance with GMP is crucial for maintaining product integrity throughout the supply chain.

- European Medicines Agency (EMA) Guidelines: In Europe, specific guidelines dictate how medicines should be packaged to ensure safety and efficacy. These guidelines cover everything from labeling requirements to environmental considerations regarding packaging disposal.

- Food and Drug Administration (FDA) Regulations: In the United States, the FDA oversees pharmaceutical packaging standards to protect public health by ensuring that all medications are labeled correctly and safely packaged.

Despite advancements, challenges remain in medicine packaging:

- Counterfeit Products: Counterfeit medications pose a significant risk to public health. Effective packaging design can help mitigate this issue through unique identifiers like barcodes or holograms that authenticate products at various points in the supply chain.

- Environmental Concerns: The push for sustainable packaging solutions has led manufacturers to explore biodegradable materials while maintaining product integrity. However, balancing sustainability with cost-effectiveness remains a challenge for many companies.

- Changing Regulations: As regulations evolve globally, pharmaceutical companies must stay informed about new requirements to avoid compliance issues that could lead to costly recalls or legal challenges.

As we look ahead, several trends are shaping the future of medicine paper boxes:

1. Sustainability: Increased focus on eco-friendly materials will continue to grow as consumers demand greener options. Companies are exploring plant-based inks and biodegradable materials that minimize environmental impact without compromising quality.

2. Personalization: Customization options may become more prevalent as brands seek to differentiate themselves in a crowded market. Personalized packaging can enhance customer loyalty by creating a unique experience tailored to individual preferences.

3. Integration with Digital Technologies: The incorporation of digital elements into packaging will enhance consumer engagement and provide valuable product information. For instance, augmented reality (AR) features could allow consumers to visualize how to use a medication properly through their smartphones.

4. Enhanced Security Features: As counterfeit drugs become more sophisticated, pharmaceutical companies will need to invest in advanced security features such as serialization codes that track products through the supply chain effectively.

5. Focus on User-Centric Design: More emphasis will be placed on designing packages that cater specifically to patient needs—making them easier to open for elderly patients or those with disabilities while ensuring child resistance where necessary.

Medicine paper boxes play a vital role in the pharmaceutical industry by ensuring product safety, providing essential information, and enhancing brand visibility. As technology advances and consumer expectations evolve, these boxes will continue to adapt, ensuring they meet both regulatory requirements and user needs effectively.

The importance of understanding medicine paper boxes cannot be overstated; they serve as a bridge between manufacturers and consumers, conveying critical information while protecting valuable medications from potential harm. With ongoing innovations in materials and design practices, we can expect these packages not only to fulfill their primary roles but also to contribute positively toward sustainability efforts within the industry.

---

1. What is the primary purpose of a medicine paper box?

- The primary purpose is to protect medications from external factors while providing necessary information about usage and safety.

2. What materials are commonly used for medicine paper boxes?

- Common materials include cardboard, coated papers, and recycled materials for sustainability.

3. How do medicine paper boxes contribute to medication safety?

- They protect against tampering, ensure proper storage conditions are communicated, and provide clear labeling to avoid dispensing errors.

4. What regulations govern the design of medicine paper boxes?

- Regulations such as Good Manufacturing Practices (GMP) and specific guidelines from health authorities like the EMA dictate how medicines should be packaged.

5. What future trends can we expect in medicine packaging?

- Trends include increased sustainability efforts, personalization options for branding, integration with digital technologies for enhanced consumer engagement, enhanced security features against counterfeiting, and a focus on user-centric design improvements.

---