- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 205 Author: XianDa Publish Time: 2024-12-12 Origin: Site

Content Menu

● Small Medicine Box: A Comprehensive Guide to Portable Healthcare Solutions

● The Importance of a Small Medicine Box

>> Benefits of Using a Small Medicine Box

● Types of Small Medicine Boxes

● The Role of Medicine Paper Box Factories

>> Manufacturing Process in Medicine Paper Box Factories

● Features to Look for in a Small Medicine Box

● Customization Options from Medicine Paper Box Factories

● Organizing Your Small Medicine Box

● The Impact of Medicine Paper Box Factories on Healthcare

● Innovations in Small Medicine Box Design

● Choosing the Right Small Medicine Box for Your Needs

● The Future of Small Medicine Boxes and Medicine Paper Box Factories

In today's fast-paced world, the importance of having a well-organized and easily accessible small medicine box cannot be overstated. Whether you're traveling, at work, or simply at home, a compact and efficient storage solution for your medications and first-aid supplies is essential. This article will explore the various aspects of small medicine boxes, their benefits, and how they contribute to better healthcare management. We'll also delve into the manufacturing process, with a focus on medicine paper box factories.

A small medicine box serves as a portable pharmacy, allowing you to carry essential medications and first-aid items wherever you go. It's not just about convenience; it's about being prepared for unexpected health situations and maintaining your well-being on the go.

1. Organization: Keeps medications and supplies neatly arranged.

2. Portability: Easy to carry during travel or daily commutes.

3. Safety: Prevents medication mix-ups and protects from environmental factors.

4. Accessibility: Quick access to necessary items in emergencies.

5. Compliance: Helps in adhering to medication schedules.

There are various types of small medicine boxes available in the market, catering to different needs and preferences.

Plastic medicine boxes are lightweight, durable, and often come with multiple compartments for organizing different medications. They are typically water-resistant and easy to clean, making them an ideal choice for everyday use.

Plastic medicine box with multiple compartments

Metal medicine boxes offer enhanced durability and a sleek appearance. They are ideal for those who prefer a more robust storage solution. Some models come with a locking mechanism for added security, making them suitable for storing prescription medications.

Metal medicine box with a locking mechanism

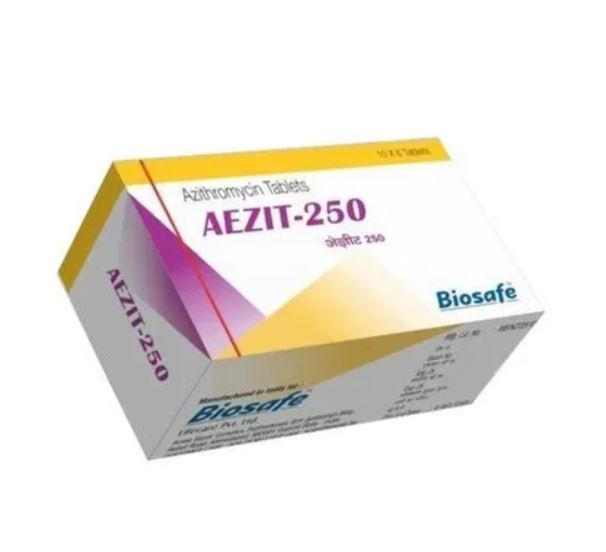

Paper medicine boxes, often produced by specialized medicine paper box factories, are eco-friendly and customizable. They are particularly popular for packaging prescription medications due to their lightweight nature and ability to be printed with important information.

Customized paper medicine box

Medicine paper box factories play a crucial role in the pharmaceutical industry by producing high-quality, customized packaging solutions for medications. These factories specialize in creating small medicine boxes that are not only functional but also aesthetically pleasing and compliant with industry regulations.

The production of small medicine boxes in a medicine paper box factory involves several steps:

1. Design and Prototyping: Creating the box design based on client specifications.

2. Material Selection: Choosing appropriate paper and cardboard materials that meet safety standards.

3. Printing: Applying branding and essential information using high-quality inks.

4. Die-Cutting: Cutting the paper into the required shape using precision machinery.

5. Folding and Gluing: Assembling the box structure to ensure durability.

6. Quality Control: Ensuring each box meets industry standards through rigorous testing.

When choosing a small medicine box, consider the following features:

1. Size and Portability: Ensure it fits your needs without being too bulky.

2. Compartments: Multiple sections for organizing different medications effectively.

3. Labeling System: Clear labeling to avoid confusion over contents.

4. Durability: Sturdy construction to protect contents from damage.

5. Childproof Locks: Safety features to prevent accidental access by children.

6. Water-Resistance: Protection against moisture and spills that could compromise medication integrity.

Features of a well-designed small medicine box

Medicine paper box factories offer a wide range of customization options for small medicine boxes. This allows pharmaceutical companies and healthcare providers to create packaging that is both functional and brand-aligned.

- Size and Shape: Tailored to specific medication dimensions for optimal fit.

- Printing: High-quality graphics and text for branding and essential information.

- Materials: Selection of paper types that provide varying levels of durability.

- Special Finishes: Options like embossing, foil stamping, or UV coating for added appeal.

- Inserts: Custom-designed inserts for additional product protection during transit.

Customized medicine boxes from a paper box factory

Proper organization of your small medicine box is crucial for its effectiveness. Here are some tips:

1. Group Similar Items: Keep like medications together to simplify access.

2. Use Labels: Clearly label each compartment or medication to avoid confusion during emergencies.

3. Check Expiration Dates: Regularly review contents and replace expired items promptly.

4. Include a List: Keep a list of contents along with dosage instructions for easy reference.

5. Separate Prescription and Over-the-Counter Medications: Avoid confusion by keeping these categories distinct.

Well-organized small medicine box

Medicine paper box factories contribute significantly to the healthcare industry by:

1. Ensuring Medication Safety: Producing packaging that protects medications from environmental factors such as moisture, light, and air exposure.

2. Promoting Compliance: Creating boxes with clear labeling that helps patients adhere to their medication schedules effectively.

3. Supporting Sustainability: Using eco-friendly materials in packaging production aligns with global sustainability goals.

4. Enhancing Patient Experience: Designing user-friendly packaging that simplifies access to medications can improve overall patient satisfaction.

5. Facilitating Supply Chain Efficiency: Producing standardized packaging solutions streamlines distribution processes across various healthcare settings.

The field of small medicine box design is constantly evolving, with new innovations emerging to improve functionality and user experience.

Smart medicine boxes incorporate technology to help users manage their medications more effectively. Features may include:

- Automatic Dispensing: Releasing the correct medication at scheduled times based on user settings.

- Reminder Alerts: Sending notifications to users' smartphones or devices when it's time to take medication or refill supplies.

- Tracking and Reporting: Monitoring medication adherence through integrated apps that generate reports for healthcare providers or caregivers.

Smart medicine box with digital display

Medicine paper box factories are increasingly focusing on sustainable packaging solutions:

- Biodegradable Materials: Using materials that break down naturally over time instead of contributing to landfill waste.

- Recycled Paper: Incorporating recycled content into production processes reduces environmental impact while maintaining quality standards.

- Minimalist Design: Reducing material usage without compromising functionality helps lower production costs while promoting sustainability.

Eco-friendly medicine boxes made from recycled materials

Selecting the appropriate small medicine box depends on various factors:

1. Usage Frequency: Daily use vs. emergency preparedness should influence your choice.

2. Number of Medications: Assess how many compartments you need based on your medication regimen.

3. Lifestyle Considerations: Consider portability if you travel frequently or have an active lifestyle requiring easy access to medications on-the-go.

4. Special Requirements: Address specific needs such as temperature control if you have sensitive medications that require refrigeration or special handling conditions.

5. Budget Constraints: Balance cost with features; sometimes investing in higher-quality materials pays off in durability over time.

As healthcare continues to evolve, so too will the design and production of small medicine boxes. Medicine paper box factories are likely to see advancements in:

1. Personalization Options: Tailoring boxes specifically to individual patient needs based on their unique health conditions or preferences can enhance user experience significantly.

2. Integration with Digital Health Technologies: Connecting packaging with health tracking apps will allow users greater control over their medication management routines while providing valuable data insights back to healthcare providers.

3. Advanced Materials Development: New materials that offer better protection against environmental factors while remaining lightweight may emerge as technology advances within manufacturing processes.

4. Automation Improvements within Production Facilities: Increasing efficiency through automation can lead not only improve output rates but also allow manufacturers greater flexibility when responding quickly changing market demands or consumer preferences without sacrificing quality standards upheld by regulatory bodies governing pharmaceutical packaging practices worldwide

5. Regulatory Compliance Adaptation: Staying ahead regulatory changes ensures continued adherence safety requirements while fostering trust among consumers who rely upon these products safeguard health outcomes throughout various stages life cycle—from initial purchase through eventual disposal once no longer needed.

Futuristic concept of a small medicine box

Small medicine boxes play a vital role in personal healthcare management, offering organization, portability, and safety for medications and first-aid supplies alike! The contribution made by dedicated teams working within specialized facilities—such as those found within many reputable medicine paper box factories — cannot be overstated; they create essential items needed support individuals' well-being every day! As we look towards future possibilities ahead—continued innovation surrounding design & functionality will undoubtedly enhance patient care experiences while improving overall medication management practices across diverse populations worldwide!

1. Q: How often should I replace my small medicine box?

A: It's recommended to replace your small medicine box every 1-2 years or sooner if it shows signs of wear and tear that could compromise the safety of its contents.

2. Q: Can medicine paper box factories produce custom designs for individuals?

A: While most medicine paper box factories primarily cater to large-scale pharmaceutical orders, some may offer custom designs for individuals or small businesses depending on their minimum order requirements.

3. Q: Are there regulations governing the production of small medicine boxes?

A: Yes, there are regulations governing the production of pharmaceutical packaging including small medicines boxes which vary by country but generally ensure that packaging is safe tamper-evident providing necessary information consumers need make informed decisions regarding usage products contained therein!

4 . Q: How can I ensure my small medicines are childproof?

A:Look out specifically designed models certified child-resistant; these typically feature locking mechanisms difficult young children open yet still accessible adults needing access contents safely!

5 . Q: What materials commonly used by medicine paper box factories?

A: Commonly utilized materials include cardboard/paperboard along specialized coated papers meet stringent pharmaceutical packaging standards ensuring safety durability throughout lifecycle product usage!