- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 202 Author: XianDa Publish Time: 2024-12-11 Origin: Site

Content Menu

● Medical Medicine Box: A Comprehensive Guide

● The Importance of Medical Medicine Boxes

● Types of Medical Medicine Boxes

>> 3. Hospital Dispensary Boxes

>> 5. Controlled Substance Boxes

● The Medicine Paper Box Factory: Behind the Scenes

● Innovations in Medical Medicine Box Design

>> Temperature-Sensitive Indicators

● Regulatory Compliance in Medicine Box Production

● The Global Market for Medical Medicine Boxes

● Customization and Branding in Medicine Box Production

● Environmental Considerations in Medicine Box Production

● The Role of Technology in Medicine Box Manufacturing

>> Automation

>> 3D Printing

● Future Trends in Medical Medicine Box Design

● The Impact of Medical Medicine Boxes on Patient Care

● Challenges Facing Medicine Paper Box Factories

In the realm of healthcare and pharmaceutical industries, the medical medicine box plays a crucial role in safeguarding and organizing medications. These boxes, often produced by specialized medicine paper box factories, are designed to meet the stringent requirements of the medical field. This article delves into the various aspects of medical medicine boxes, their importance, and the intricate process of their production.

Medical medicine boxes serve several critical functions in healthcare settings:

1. Organization: They help healthcare professionals and patients keep medications organized and easily accessible.

2. Protection: These boxes shield medications from environmental factors such as light, moisture, and temperature fluctuations.

3. Safety: Properly labeled boxes reduce the risk of medication errors.

4. Compliance: They aid patients in adhering to their prescribed medication regimens.

5. Information: Many boxes include important drug information and dosage instructions.

Medical Medicine Box Importance

There are various types of medical medicine boxes available, each designed for specific purposes:

These boxes are divided into compartments for different days of the week and times of day. They are particularly useful for patients with complex medication regimens.

Daily Pill Organizer

Compact and portable, these boxes are ideal for patients who need to carry medications while traveling. They often feature secure closures to prevent accidental opening.

Large-scale organizers used in hospital pharmacies to store and dispense medications efficiently. These boxes are often part of automated dispensing systems.

Equipped with technology to remind patients when to take their medications and track adherence. Some advanced models can even alert caregivers or healthcare providers if doses are missed.

Specially designed boxes with enhanced security features for storing and transporting controlled substances. These boxes often include tamper-evident seals and locking mechanisms.

The production of medical medicine boxes is a complex process that requires specialized facilities and expertise. Medicine paper box factories play a crucial role in manufacturing these essential healthcare products.

The primary material used in medicine paper box factories is high-quality, pharmaceutical-grade paper or cardboard. This material must meet strict standards for purity and durability. Some factories also use specialized coatings to enhance protection against moisture and light.

Raw Materials for Medicine Boxes

Before mass production begins, medicine paper box factories engage in a meticulous design process:

1. Conceptualization: Designers work with healthcare professionals to understand specific needs.

2. 3D modeling: Advanced software is used to create precise digital models.

3. Prototype creation: 3D printing and traditional methods are used to create physical prototypes.

4. Testing and refinement: Prototypes undergo rigorous testing to ensure functionality and compliance with regulations.

The manufacturing process in a medicine paper box factory typically involves the following steps:

1. Cutting: Large sheets of paper or cardboard are cut to the required dimensions using precision machinery.

2. Printing: Box designs, labels, and important information are printed on the cut material using food-grade, non-toxic inks.

3. Die-cutting: Specialized machines create the box shape and any necessary perforations or slots.

4. Folding and Gluing: The cut and printed material is folded and glued to form the final box structure, often using automated folding machines.

5. Quality Control: Each box undergoes rigorous inspection to ensure it meets all specifications, including dimensional accuracy and print quality.

Medicine Box Manufacturing Process

Medicine paper box factories are constantly innovating to improve the functionality and sustainability of their products:

Integration of QR codes and NFC tags for easy access to medication information and tracking. This technology allows patients to quickly access drug information and set reminders on their smartphones.

Development of biodegradable and recyclable materials for more sustainable packaging solutions. Some factories are experimenting with plant-based plastics and recycled paper products.

Creation of boxes with advanced locking mechanisms to prevent accidental ingestion by children. These designs must balance safety with accessibility for elderly or disabled patients.

Child-resistant Medicine Box

Some advanced medicine boxes now include temperature-sensitive strips or indicators that change color if the medication has been exposed to extreme temperatures during storage or transport.

Medicine paper box factories must adhere to strict regulations set by health authorities:

- FDA guidelines in the United States

- EMA standards in Europe

- WHO recommendations for global distribution

These regulations ensure that medical medicine boxes meet the highest standards of safety and quality. Compliance often involves:

- Regular audits of manufacturing facilities

- Documentation of quality control processes

- Traceability of materials and finished products

- Adherence to Good Manufacturing Practices (GMP)

The demand for medical medicine boxes is growing rapidly, driven by:

- Aging populations in developed countries

- Increasing prevalence of chronic diseases

- Expansion of healthcare services in developing nations

- Growing awareness of the importance of medication adherence

Medicine paper box factories are expanding their operations to meet this growing demand, with many focusing on specialized products for different market segments. The global market for medical packaging, including medicine boxes, is expected to reach $120 billion by 2025.

Global Medical Medicine Box Market

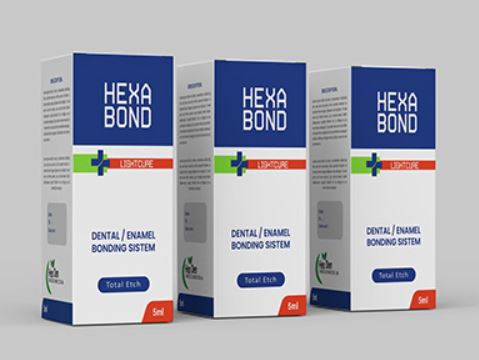

Many pharmaceutical companies work closely with medicine paper box factories to create custom packaging solutions:

- Branded designs that reinforce company identity

- Specialized shapes and sizes for unique product lines

- Integration of anti-counterfeiting features

This collaboration between pharmaceutical companies and medicine paper box factories ensures that packaging not only protects the medication but also enhances the overall brand experience for patients. Custom designs can include:

- Embossed logos

- Unique color schemes

- Specialized opening mechanisms

- Integrated patient information leaflets

As sustainability becomes increasingly important, medicine paper box factories are adopting eco-friendly practices:

- Use of recycled materials

- Implementation of energy-efficient manufacturing processes

- Development of easily recyclable packaging designs

- Reduction of packaging waste through optimized designs

These efforts not only reduce the environmental impact of medical medicine boxes but also appeal to environmentally conscious consumers and healthcare providers. Some factories are even exploring the use of plant-based inks and adhesives to further reduce their ecological footprint.

Eco-friendly Medicine Box Production

Medicine paper box factories are leveraging advanced technologies to improve production efficiency and product quality:

Robotic systems and automated production lines increase output while maintaining consistent quality. These systems can handle tasks such as:

- Precision cutting and folding

- High-speed printing

- Automated quality inspections

Rapid prototyping of new box designs allows for faster innovation and customization. 3D printing enables factories to:

- Create complex prototypes quickly

- Test multiple design iterations

- Produce small batches of specialized boxes

Quality control processes are enhanced through AI-powered visual inspection systems. These systems can detect defects that might be missed by human inspectors, ensuring higher overall quality.

Future Trends in Medical Medicine Box Design

The future of medical medicine boxes is likely to see further innovations:

1. Integration with IoT: Boxes that can communicate with smartphones and healthcare systems to improve medication adherence and provide real-time monitoring.

2. Nanotechnology: Incorporation of nanoparticles in packaging materials to enhance protection against light and moisture, potentially extending medication shelf life.

3. Personalized Medicine Packaging: Boxes designed to accommodate individualized medication regimens, potentially including on-demand printing of personalized instructions.

4. Augmented Reality: AR-enabled boxes that provide interactive instructions and information to patients, improving understanding and compliance.

Future Medicine Box Concepts

5. Biodegradable Electronics: Integration of biodegradable electronic components for smart packaging that doesn't contribute to e-waste.

Properly designed and manufactured medical medicine boxes have a significant impact on patient care:

- Improved medication adherence, leading to better health outcomes

- Reduced medication errors, enhancing patient safety

- Enhanced patient education and engagement through clear labeling and instructions

- Better management of complex treatment regimens, particularly for patients with multiple chronic conditions

Medicine paper box factories play a crucial role in enabling these benefits through their innovative designs and high-quality production processes. The collaboration between healthcare providers, pharmaceutical companies, and medicine paper box factories continues to drive improvements in patient care and medication management.

Despite the growing demand, medicine paper box factories face several challenges:

1. Regulatory Compliance: Keeping up with evolving healthcare regulations and standards across different global markets.

2. Material Costs: Fluctuations in raw material prices can impact production costs, requiring efficient supply chain management.

3. Competition: Increasing global competition requires continuous innovation and efficiency improvements to maintain market share.

4. Sustainability Pressures: Meeting consumer and regulatory demands for more environmentally friendly packaging solutions while maintaining product integrity.

5. Technological Adaptation: Investing in new technologies and training staff to operate advanced manufacturing equipment.

6. Counterfeit Prevention: Developing increasingly sophisticated anti-counterfeiting measures to protect patients and pharmaceutical brands.

Medical medicine boxes are an essential component of modern healthcare, playing a vital role in medication management and patient safety. The medicine paper box factory is at the heart of this industry, continuously innovating and adapting to meet the evolving needs of healthcare providers and patients. As technology advances and healthcare practices evolve, we can expect to see even more sophisticated and patient-centric designs emerging from these specialized manufacturing facilities.

The future of medical medicine boxes lies in the intersection of advanced materials science, smart technology, and sustainable manufacturing practices. As medicine paper box factories continue to push the boundaries of what's possible, they will play an increasingly important role in improving patient outcomes and supporting the global healthcare system.

1. Q: What materials are commonly used in medical medicine boxes?

A: Medical medicine boxes are typically made from high-quality, pharmaceutical-grade paper or cardboard. Some advanced designs may incorporate plastics, metals, or eco-friendly materials like biodegradable polymers.

2. Q: How do medicine paper box factories ensure the quality of their products?

A: Medicine paper box factories implement rigorous quality control measures, including automated inspection systems, regular testing of materials, and adherence to Good Manufacturing Practices (GMP) as required by regulatory agencies.

3. Q: Can medical medicine boxes be recycled?

A: Many medical medicine boxes are recyclable, especially those made from paper or cardboard. However, some specialized boxes with additional features or coatings may require specific recycling processes. Always check local recycling guidelines.

4. Q: How are child-resistant features incorporated into medical medicine boxes?

A: Child-resistant features in medical medicine boxes often include complex opening mechanisms, such as push-and-turn caps, or designs that require simultaneous actions that are difficult for young children to perform but manageable for adults.

5. Q: What role do medicine paper box factories play in combating counterfeit medications?

A: Medicine paper box factories incorporate various anti-counterfeiting features into their designs, such as holograms, unique serial numbers, and tamper-evident seals. They work closely with pharmaceutical companies to develop packaging that is difficult to replicate, helping to protect consumers from counterfeit medications.

AM PM Medicine Box: A Comprehensive Guide to Medication Management

Lockable Medicine Box: Ensuring Safety and Security for Your Medications

Medicine Box with Timer: A Revolutionary Solution for Medication Adherence

Hello Kitty Medicine Box: Cute and Functional Storage for Your Health Essentials

Large Medicine Box: A Comprehensive Guide to Pharmaceutical Packaging