- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 201 Author: XianDa Publish Time: 2025-02-06 Origin: Site

Content Menu

● What Does Chocolate Box Mean?

● The Essence of "Chocolate Box"

● Visual Representation & Examples

● Connotations: Beyond the Surface

● The History of the Chocolate Box: From Bean to Beauty

● The Victorian Era: A Sweet Revolution

● Richard Cadbury: The Pioneer of Packaging

● The Marketing Magic: More Than Just Sweets

● From Cocoa Bean to Chocolate Box: A Journey of Transformation

● Inside a Chocolate Box Factory: A World of Sweet Production

● The Packaging Process: A Symphony of Presentation

● Machines Used in Chocolate Packaging

● "Chocolate Box" in Contemporary Culture: Enduring Appeal

● Related Questions and Answers

The term "chocolate box" conjures up images of idyllic countryside scenes and perfectly arranged sweets. But beyond the picturesque, it carries a deeper meaning rooted in the history of chocolate, the art of marketing, and the human desire for beauty and sentimentality. This article explores the essence of "chocolate box," its historical origins, the chocolate-making process, and its continued relevance in contemporary culture. We will also peek behind the scenes at the operations of a chocolate box factory.

At its core, "chocolate box" is an adjective used to describe something that is excessively pretty, quaint, and often conventionally beautiful. It's a term often applied to places, images, or even situations that evoke a sense of idealized charm, sometimes bordering on the cliché. Think of a scene that seems almost too perfect to be real – that's the "chocolate box" aesthetic.

The term gets its visual association from the images that adorned early chocolate boxes, which frequently showcased:

Picturesque landscapes: Rolling hills, verdant meadows dotted with grazing sheep, meandering streams reflecting the clear blue sky. Think of the Cotswolds in England, or the Swiss Alps, or even a carefully manicured English garden. These images exude tranquility and pastoral beauty.

Idealized scenes: Romantic encounters in sun-dappled glades, children playing innocent games on village greens, families gathered around cozy hearths in rustic cottages. These scenarios present a vision of harmony and domestic bliss.

Sentimental imagery: Roses in full bloom, cherubic figures representing love, and ornate lettering conveying messages of affection. These elements tap into emotions of warmth, nostalgia, and longing.

While "chocolate box" generally carries positive connotations, implying beauty and charm, it can also be used critically. It might suggest:

Lack of Depth: A focus on superficial appearance at the expense of substance. Something described as "chocolate box" might be seen as pretty but lacking in originality, authenticity, or intellectual stimulation.

Artificiality: A manufactured or contrived beauty, rather than something genuine or naturally occurring. The scene might appear staged or overly polished, devoid of the imperfections that give real life its character.

Sentimentality: An excess of emotion, bordering on the saccharine. A "chocolate box" image might be seen as overly romanticized or sentimental, appealing to emotions in a way that feels cloying or insincere.

The story of the "chocolate box" is inextricably linked to the evolution of chocolate itself. From its origins as a bitter ceremonial drink among the ancient Mayans and Aztecs to its transformation into a global confectionery phenomenon, chocolate has undergone a remarkable journey. The development of the chocolate box was a key chapter in this history, playing a crucial role in popularizing chocolate as a gift, a symbol of affection, and a source of everyday pleasure.

The Victorian era (1837-1901) was a period of profound social, economic, and technological change. It was also a time of growing consumerism and an increasing appetite for affordable luxuries. The rise of chocolate as a commercially viable product coincided with this trend, and the chocolate box emerged as a clever marketing strategy to capitalize on the Victorian love of beauty and sentimentality.

Richard Cadbury, a member of the famous British chocolate manufacturing family, is widely credited with creating the first modern chocolate box. In 1861, he ingeniously repurposed excess cocoa butter, a byproduct of the cocoa extraction process, to create smoother, more palatable eating chocolate. Recognizing the potential for chocolate as a gift, particularly for Valentine's Day, Cadbury began packaging his chocolates in beautifully decorated boxes.The very first Cadbury chocolate box, launched in 1868, was a heart-shaped container adorned with romantic floral motifs and Cupid imagery. These boxes weren't just functional packaging; they were designed to be cherished as keepsakes, repurposed as jewelry boxes, or used to store mementos long after the chocolates had been enjoyed. This dual-purpose design was a stroke of marketing genius.

Cadbury's innovation went beyond mere confectionery. By presenting chocolates in aesthetically pleasing and reusable boxes, he transformed the product into a desirable gift item. The boxes themselves became objects of desire, enhancing the overall appeal of the chocolate and creating a sense of luxury and indulgence. This marketing approach proved incredibly successful, establishing Cadbury as a leading chocolate manufacturer and popularizing the chocolate box as a symbol of affection.

The journey from the cocoa bean to the final product in a chocolate box factory is a complex and intricate process, involving several stages of transformation:

Harvesting and Fermentation: Cocoa beans are harvested from the cocoa tree, fermented to develop their flavor, and then dried.

Roasting: The dried beans are roasted to further enhance their flavor and aroma.

Grinding and Processing: The roasted beans are ground into a cocoa liquor, which is then separated into cocoa butter and cocoa solids.

Mixing and Refining: Cocoa liquor, cocoa butter, sugar, and other ingredients (such as milk powder in milk chocolate) are mixed together and refined to create a smooth, consistent texture.

Conching: This crucial step involves prolonged mixing and agitation of the chocolate mixture, further refining the texture and developing the flavor.

Tempering: The chocolate is carefully heated and cooled to stabilize the cocoa butter crystals, giving it a glossy appearance and a crisp snap.

Molding and Enrobing: The tempered chocolate is poured into molds to create various shapes and sizes, or used to enrobe other ingredients, such as nuts or fruits.

Cooling and Demolding: The molded chocolates are cooled to solidify and then removed from the molds.

Quality Control: Before Packaging, the products will go through multiple stages of quality control.

Packaging: The final stage involves carefully packaging the chocolates into boxes, wrappers, and other containers, ready for distribution.

A chocolate box factory is a hive of activity, a place where raw ingredients are transformed into delectable treats. These factories employ a range of specialized machinery and skilled workers to produce chocolate in various forms, from bars and truffles to individually wrapped chocolates destined for beautifully decorated boxes. The process is a blend of art and science, requiring precision, expertise, and a keen understanding of the properties of chocolate.

The packaging process in a chocolate box factory is as crucial as the chocolate-making itself. It's not just about containing the chocolates; it's about preserving their quality, protecting them from damage, and, most importantly, appealing to consumers. The packaging must be functional, attractive, and reflective of the brand's identity.The steps involved in chocolate packaging include:

Preparation: Ensuring that all packaging materials, such as boxes, wrappers, and labels, are readily available and meet quality standards.

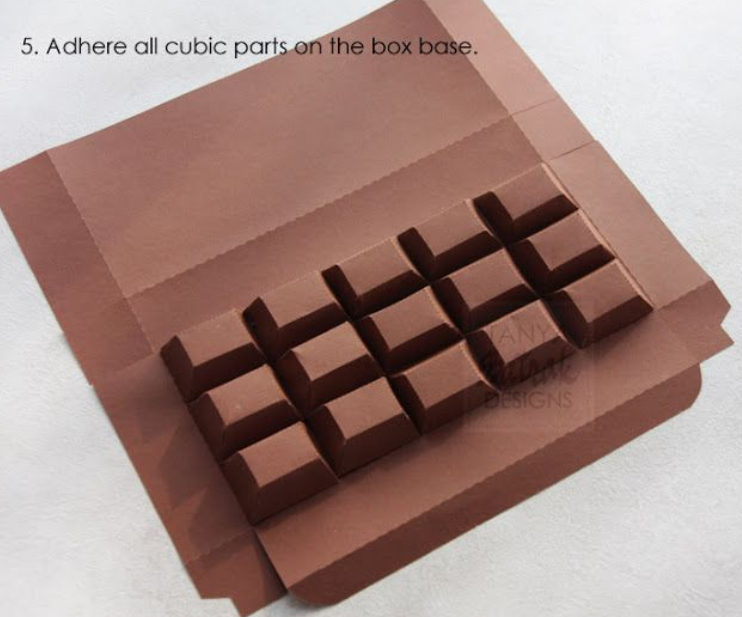

Forming: Creating the packaging containers, whether it's folding cardboard boxes, sealing plastic wrappers, or applying foil linings.

Packing: Placing the chocolates into the formed containers, often using automated machinery to ensure speed and accuracy.

Sealing: Sealing the packages to create an airtight closure, preventing moisture and contaminants from affecting the chocolate's quality.

Labeling: Applying labels that provide information about the product, including ingredients, nutritional information, and branding.

Quality Control: Inspecting the finished packages to ensure that they meet quality standards for appearance, sealing, and labeling.

Discharge: Removing the completed packages from the production line for further distribution to retailers and consumers.

Chocolate Depositor Machine: These machines ensure that chocolate is measured accurately.

Forming Collars: Aids in the formation of packing material.

Automated Packaging Lines: These complex systems automate many of the packaging steps, increasing efficiency and reducing labor costs.

Robotic Arms: Used for delicate tasks such as placing chocolates in specific arrangements within the box.

The term "chocolate box" continues to resonate in modern culture, often used to describe:

Tourism: Charming villages and scenic destinations that offer a quintessential, picture-perfect experience.

Art and Design: Works that are overly sentimental, prettified, or lacking in originality.

Literature and Film: Settings that are idealized or unrealistic, creating a sense of escapism and fantasy.

The "chocolate box" aesthetic still holds a certain appeal, offering a comforting vision of beauty and tranquility.

What is the origin of the term "chocolate box"?

The term originated in the Victorian era with Richard Cadbury's introduction of beautifully decorated boxes of chocolates.

What are the typical characteristics of a "chocolate box" scene?

Typical characteristics include picturesque landscapes, idealized scenes, and sentimental imagery.

Is the term "chocolate box" always positive?

While generally positive, the term can also imply a lack of authenticity or originality.

What is the significance of the heart-shaped chocolate box?

The heart-shaped box, first introduced by Cadbury for Valentine's Day, became a symbol of love and affection.

What are the main steps in the chocolate manufacturing process?

The main steps include raw material pretreatment, mixing, fine grinding, conching, tempering, and molding.