- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 196 Author: XianDa Publish Time: 2025-01-24 Origin: Site

Content Menu

● Introduction to Perfume Box Manufacturing

● The Importance of Perfume Packaging

● Stages of Perfume Box Manufacturing

● Innovative Techniques in Perfume Box Manufacturing

● The Role of Technology in Manufacturing

● Case Study: A Leading Perfume Box Factory

● Trends in Perfume Box Design

● Frequently Asked Questions (FAQs)

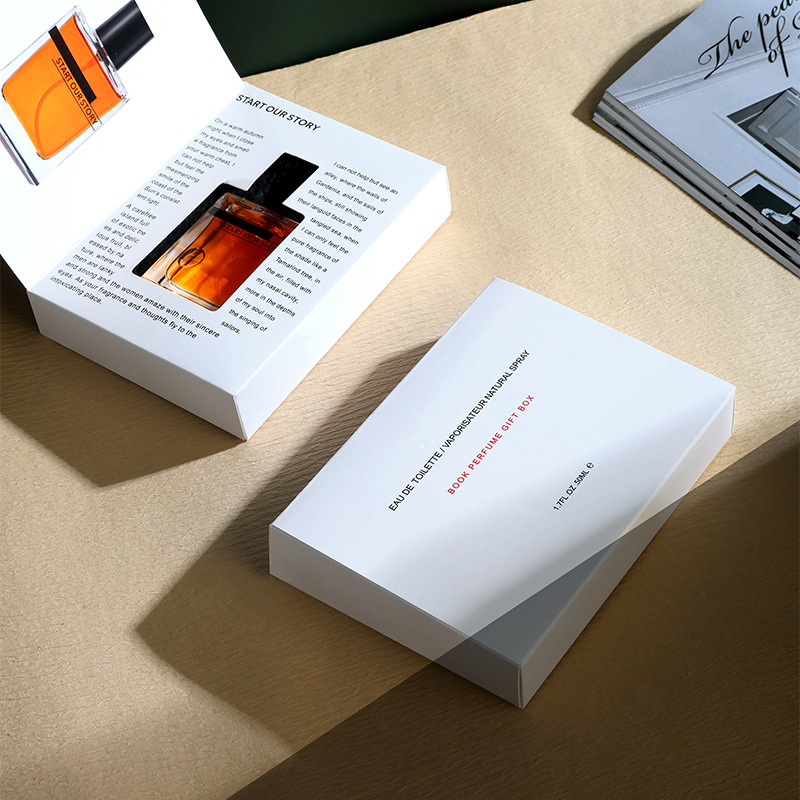

The perfume industry is not just about the fragrances themselves; it also heavily relies on packaging to attract consumers and convey brand identity. The perfume box factory plays a crucial role in this process, producing boxes that are not only functional but also aesthetically pleasing. This article delves into the intricate world of perfume box manufacturing, exploring the various stages involved, the materials used, and the innovative techniques that enhance the final product.

Perfume packaging serves several vital functions:

Protection: It safeguards the delicate fragrance from environmental factors such as light, heat, and moisture. Proper packaging ensures that the scent remains intact until it reaches the consumer.

Branding: The design communicates the brand's identity and values. A well-crafted box can tell a story about the fragrance inside, reflecting its inspiration and target audience.

Consumer Attraction: Eye-catching packaging can influence purchasing decisions. In a market saturated with options, a unique and appealing design can make all the difference.

The visual aspect of perfume boxes is critical. A well-designed box can create an emotional connection with consumers, making them more likely to choose that product over others. Elements like color, texture, and shape play significant roles in how a product is perceived.

The manufacturing process of perfume boxes involves several key stages:

This initial stage is where creativity meets strategy. Designers collaborate with brands to create a box that embodies the fragrance's character. Factors considered include:

Color Schemes: Colors evoke emotions and can significantly influence consumer perception. For instance, soft pastels may suggest femininity, while bold colors might indicate luxury or vibrancy.

Typography: The choice of fonts and text layout can convey sophistication or playfulness, aligning with the brand's overall message.

Imagery: Graphics and illustrations on the box should resonate with the target audience and reflect the scent's essence.

Choosing the right materials is crucial for achieving the desired look and feel. Common materials include:

Cardboard: Versatile and cost-effective, cardboard is widely used for its ability to be printed on easily and its strength.

Plastic: Durable and often used for luxury packaging, plastic can provide a modern aesthetic but may raise sustainability concerns.

Sustainable Materials: Increasingly popular due to environmental concerns, options like recycled paper or biodegradable materials are becoming standard in many perfume box factories.

Once designs are finalized, production begins. Key techniques include:

Precision Cutting: This process shapes the box accurately using advanced machinery like laser cutters or die-cutting machines.

Folding and Assembling: Creating the structure involves folding techniques that ensure durability while maintaining an elegant appearance.

Finishing Touches: Applying laminates for gloss or matte finishes, embossing for texture, or foil stamping for luxury appeal enhances visual attractiveness.

Quality checks ensure that every box meets industry standards and brand specifications. This includes inspecting materials for defects, ensuring designs are printed correctly, and confirming that assembly is flawless. Quality control is essential to maintain brand reputation and customer satisfaction.

After production, boxes are securely packaged for shipping to ensure they arrive in perfect condition. This stage may involve:

Using protective materials like bubble wrap.

Ensuring boxes are stacked properly to prevent damage during transit.

Labeling packages accurately for efficient delivery.

As consumer preferences evolve, so do packaging techniques. Here are some innovative methods currently being used:

Color-Changing Materials: Some brands use materials that change color with temperature or light exposure, creating an interactive experience for consumers.

Die-Cutting: Intricate designs that enhance visual appeal can be achieved through advanced die-cutting techniques, allowing for unique shapes and cutouts that draw attention.

With a growing emphasis on sustainability, many manufacturers are adopting eco-friendly practices:

Using recyclable materials helps reduce waste.

Minimizing waste during production through efficient cutting layouts.

Implementing energy-efficient machinery to lower carbon footprints.

Technological advancements have revolutionized perfume box manufacturing:

Automation: Increases efficiency by automating repetitive tasks such as cutting and assembling boxes. This reduces human error and speeds up production times.

Advanced Machinery: Allows for complex designs to be produced quickly and accurately. High-speed printing technology enables vibrant graphics to be applied directly onto boxes with precision.

Digital prototyping tools allow designers to create virtual models of their packaging before physical production begins. This technology enables brands to visualize their designs in real-time and make adjustments as needed without incurring high costs associated with physical samples.

One notable example is Hongyi Packaging, which specializes in creating custom perfume boxes. Their process includes:

Initial Design Discussions with Clients: Understanding client needs and brand identity.

Sample Creation for Approval: Producing prototypes for client feedback before full-scale production begins ensures satisfaction with design elements.

Full-Scale Production with Rigorous Quality Control Measures: Implementing strict quality checks at every stage of production guarantees high standards are met consistently.

Sustainability Initiatives: Hongyi Packaging has integrated sustainable practices into their operations by using eco-friendly materials and minimizing waste throughout their processes.

As consumer preferences shift towards personalization and sustainability, several trends have emerged in perfume box design:

Minimalist designs focus on simplicity and elegance. Clean lines, muted colors, and straightforward typography create a sophisticated look that appeals to modern consumers looking for understated luxury.

Personalized packaging allows customers to feel more connected to the product. Brands are increasingly offering customizable options where consumers can add their names or choose specific designs that resonate with them personally.

Interactive elements such as QR codes or augmented reality features engage consumers further by providing additional information about the fragrance or an immersive experience related to the brand story.

The journey from concept to shelf for a perfume box is complex and multifaceted. It requires a careful blend of artistry, engineering, and innovation to create packaging that not only protects but also enhances the brand's identity. As consumer preferences shift towards sustainability and unique designs, perfume box factories must adapt to stay competitive in this dynamic market.In summary, understanding every aspect of perfume box manufacturing—from design through production—enables brands to create compelling packaging that resonates with consumers while reflecting their values.

What materials are commonly used in perfume box manufacturing?

Common materials include cardboard, plastic, metal, and sustainable options like recycled paper.

How does design influence consumer behavior?

A well-designed box can attract consumers' attention and create an emotional connection, influencing their purchase decisions.

What are some innovative features in modern perfume packaging?

Innovations include color-changing materials and intricate die-cut designs that enhance visual appeal.

Why is sustainability important in perfume packaging?

As consumers become more environmentally conscious, brands that use sustainable practices can attract a larger customer base.

What role does technology play in the manufacturing process?

Technology streamlines production processes, increases efficiency, and allows for more complex designs to be created accurately.